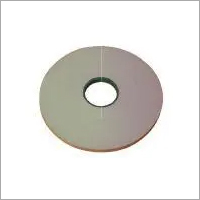

C Core

C Core Specification

- Usage

- Used in Instrument Transformers, power transformers, inductors, transducers

- Product Type

- C-Core Eith Clamp

- Material

- Metal

- Feature

- Long Working Life and High Strength

- Color

- Black

C Core Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 500 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Carton Box

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia, Africa

- Main Domestic Market

- All India

About C Core

Pair of Laminated C-Core with clamp.These type of cores are used in instrument transformers, power

transformers, inductors, transducers, variable - ratio transformers,

insulation transformers, pulse transformers, AC-DC chokes, high

frequency rectiers and special transformers.

C- Cores are strip wound,

impregnated and cut into

two halves. Since these

cores are assembled around

the bobbins in a very short

time it takes less time to

manufacture the transformer.

High Durability and Strength

The C Core is crafted with superior metal materials, ensuring remarkable durability and resilience. Its unique structure offers enhanced mechanical strength, making it suitable for use in settings where longevity and reliability are crucial. This means reduced maintenance and consistent performance over the years.

Versatile Applications

Designed for versatility, our C Core finds application in instrument transformers, power transformers, inductors, and transducers. Its compatibility with different devices makes it a preferred component for both industrial and commercial electrical projects. This flexibility extends its value across diverse sectors.

FAQs of C Core:

Q: How is the C Core used in instrument and power transformers?

A: The C Core serves as a magnetic core, facilitating efficient energy transfer and voltage regulation in instrument and power transformers. Its high magnetic permeability helps optimize transformer performance and minimizes energy loss.Q: What are the benefits of using a high-strength C Core in electrical devices?

A: Using a high-strength C Core ensures greater mechanical stability and reliability in your devices. Its long working life reduces downtime and maintenance costs, making it ideal for critical applications in transformers and inductors.Q: When should I choose a C Core for my project?

A: You should select a C Core when your project requires superior magnetic performance, structural integrity, and long-term durability. It is especially suitable for environments where consistent, high-efficiency operation is essential.Q: Where are C Cores typically installed?

A: C Cores are commonly installed inside the magnetic circuits of transformers, inductors, and transducers. Their standardized size and shape make them suitable for integration into a wide array of electrical equipment.Q: What is the manufacturing process for your C Cores?

A: Our C Cores are manufactured using advanced metallurgical techniques that involve shaping and heat-treating high-grade metal alloys. The process ensures optimal magnetic properties, structural strength, and a uniform black finish.Q: What makes your C Core a reliable choice for export from India?

A: As a recognized exporter and manufacturer, we adhere to stringent quality standards and utilize tested materials. Our products are engineered for international reliability and performance, making them a trusted choice for clients globally.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electricity & Magnetism Category

Van De Graff Generator Hand Driven

Price Range 1000.00 - 5000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Hand Driven Van De Graff Generator

Feature : Long Working Life and High Strength

Color : Silver and Red

Material : Steel

Electrostatic Kit, For Laboratory

Price Range 1000.00 - 5000.00 INR / Kit

Minimum Order Quantity : 10 Kits

Product Type : Electrostatic Kit

Feature : Long Service Life and High Functionality

Color : White, Black and Blue

Material : Aluminum, Polythene, Nylon and Rubber

Round Ticker Timer Tape

Price Range 50.00 - 300.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Ticker Timer Tape

Feature : Long Working Life

Color : Gray

Material : Metal

Shinco Demonstration Meter

Price Range 1000.00 - 5000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Demonstration Meter

Feature : Corrosion Resistance

Color : White and Black

Material : Plastic and Metal

SCI-LAB SOLUTION

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS